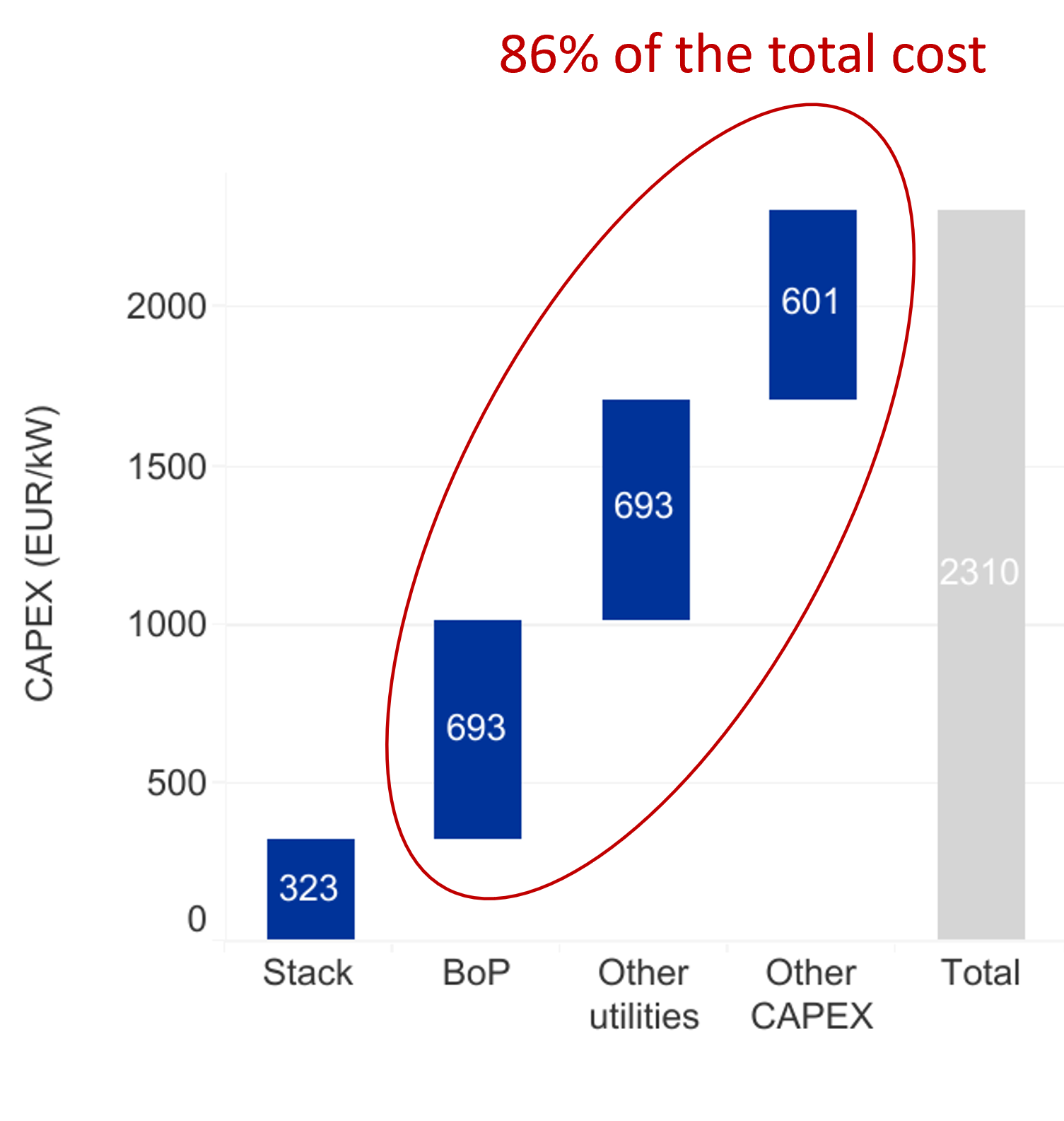

The total stack cost for alkaline electrolysers are 14 percent of total costs.

it's actually the balance of plant (BoP) and surrounding systems that account for up to 86% of total system cost.

The stack cost includes equipment, engineering, procurement, and installation of the stack.

The balance of plant cost includes equipment, engineering, procurement, and installation of rectifier, transformer directly connected to the rectifier, gas/liquid separation, water/lye feeding, and gas purification.

Other utilities costs include equipment, engineering, procurement, and installation of high voltage transformers, water treatment equipment, cooling, hydrogen compression (if necessary for the system), control system, and other services.

The other CAPEX costs include land and grid fees, insurance, permitting, feasibility study, contingency, EPC management.