Example Use Case: Alkaline Electrolysers for Efficient Hydrogen Production

Cutting hydrogen costs where it matters most

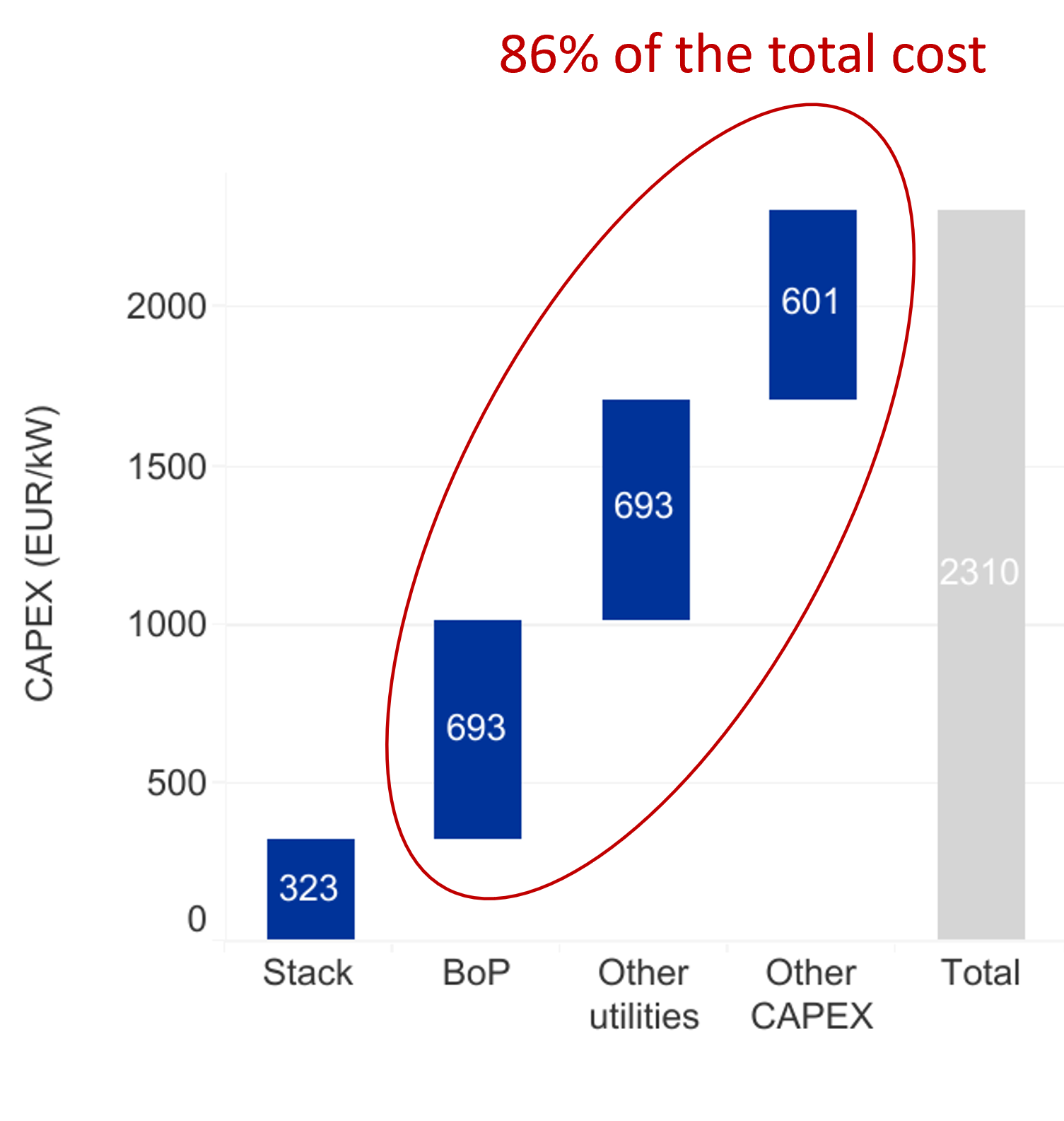

Based on European Hydrogen Observatory data, the cost alkaline electrolyser stack is only 14% of total CAPEX costs. While Balance of Plant (BoP) and surrounding system contributes to 86% of the total CAPEX of alkaline electrolyser systems.

The Balance of Plant (BoP) and surrounding systems are the biggest contributor to high CAPEX and running costs. These data showing that much of these costs stems from fundamental physical challenges that haven’t been solved within the electrolyser stack itself.

While most industry efforts have focused on improving stack performance, FlowVolta addressed the overlooked cost drivers: the Balance of Plant (BoP) and surrounding systems. Our proprietary electrolyser design simplifies system architecture, reduces auxiliary equipment requirements, and optimizes energy and water management.

By re-engineering the flow and integration of hydrogen generation systems, FlowVolta eliminated unnecessary complexity and lowers material and installation demands. This approach results in up to 50% reduction in non-stack costs, making green hydrogen production more economically viable and scalable.

FlowVolta shifts the paradigm: instead of incremental gains in stack efficiency, we target the true bottleneck—system-level costs—delivering a step-change in affordability and deployment speed.

Challenges with current alkaline electrolyser design

Large size and weight

Conventional alkaline electrolysers are bulky and heavy. This leads to high manufacturing costs, complicated logistics, and complex maintenance procedures—making scaling and deployment slow and costly.

High potential for failure

A typical 1 MW alkaline electrolyser contains more than 20,000 individual components. With such a high part count, even small issues can cascade into failures, driving up downtime, service costs, and reliability concerns.

Lack of system-level integration

Most designs have historically focused on improving stack efficiency, while overlooking the overall system. This has resulted in fragmented architectures that are expensive to build, difficult to integrate, and inefficient to operate.

Flowvolta's proprietary design is based on a radical simplification. An hydrogen electrolysis system built using this design is easy to assemble and install, significantly reducing manufacturing and deployment complexity. Its low weight makes transportation and logistics straightforward, while the streamlined architecture ensures a simple balance of plant (BoP) with far fewer auxiliary components. Each cell is fully accessible, repairable, and replaceable, which greatly improves reliability, minimizes downtime, and lowers long-term operating costs.

Unlocking cheap hydrogen

Cheap hydrogen can only be unlocked by addressing the biggest barriers that stand in the way of cost-effective production. Today’s electrolysers suffer from limited operational flexibility, with many pressurised alkaline systems unable to operate below 40% load. Stacks and systems are also unreliable, which increases operating costs and slows down the process of building a strong performance track record. In addition, the high capital costs of installing hydrogen projects remain a major obstacle to scale and competitiveness.

Using FlowVolta's proprietary design, H2 electrolysers can overcome these barriers. Such an electrolyser will have full operational flexibility from 0–100% load, while remaining robust under instantaneous starts and stops. The design eliminates reverse current, a major source of efficiency loss and failure in conventional systems, and ensures very low electrode degradation under real operating conditions. This combination of flexibility, durability, and reliability dramatically reduces both running costs and capital requirements, unlocking the pathway to truly affordable hydrogen.